close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Electrofusion fittings join polyethylene pipes. They use built-in heating coils. These coils melt the pipe and fitting surfaces. This makes them stick together tightly. Many industries pick electrofusion for water and gas pipes. The process makes strong and leak-proof joints. Electrofusion is now more popular than before. Smart systems and IoT technology are used today. They help with real-time monitoring and quality checks. The table below shows fast growth and new ideas in electrofusion for pipes.

Aspect | Industry Trend |

|---|---|

Global Adoption Growth | Over 25% more smart electrofusion systems in the last 2 years |

IoT Integration | 40% of new setups use IoT for checking |

Sustainability | More people use PE pipes and electrofusion for safe, eco-friendly solutions |

Knowing about electrofusion helps installers, engineers, and maintenance teams. It lets them pick the best fittings for HDPE and MDPE piping systems.

Electrofusion fittings connect polyethylene pipes. They use heating coils inside. The coils melt the pipe and fitting. This makes them stick together tightly. The joint is strong and does not leak.

These fittings are simple to put in. They work well in small spaces. They also work in places that are hard to reach. The joints they make are stronger than the pipes.

You must prepare and clean the pipes well. You need to use the right tools. This helps make the electrofusion joint safe and strong.

Electrofusion works best for water, gas, and chemical pipes. It is good for tight spaces and repairs. Butt fusion is better for big, straight pipes and long pipe runs.

Training is important for workers. Careful checking stops common problems. This keeps electrofusion pipe systems safe and working well.

Electrofusion fittings are special parts that join polyethylene pipes. Makers use high-quality, new resin to make them. This resin must meet strict rules like ASTM F1055. Each fitting has a barcode for tracking and checking quality. Inside the fitting, there are heating coils. When electricity goes through these coils, they get hot. The heat melts the inside of the fitting and the outside of the pipe. This makes a strong joint that does not leak. Electrofusion fittings work well for pipes that move water, gas, or other liquids. Some common types are electrofusion couplings, elbows, tees, and saddles. These fittings use PE100 or PE4710, which are strong and last a long time.

Electrofusion fittings are different because of their special design and how well they work.

Tip: The heating coils inside each fitting help make the fusion exact and dependable.

Precise Fusion: The heating coils only melt the parts that need to join. This makes a tight bond at a tiny level.

Automation: Machines control the time and heat. This helps stop mistakes and gives the same results every time.

Versatility: These fittings work with many kinds of polyethylene pipes, like PE100, PE4710, and PE3608.

Strong Joints: The joint is often stronger than the pipe itself.

Easy Installation: You do not need big tools. Workers can put in fittings even in small or hard places.

Compatibility: Electrofusion fittings meet rules for water and gas, like AWWA, ASTM, and NSF.

Here is a table that shows how electrofusion fittings and butt fusion fittings are different:

Feature | Electrofusion Fittings | Butt Fusion Fittings |

|---|---|---|

Connection Method | Heating wires inside make heat, melting only the inside of the fitting and outside of the pipe. | Pipe and fitting ends are heated on the outside with a plate, then pushed together. |

Heating Area | Only the inside of the fitting and outside of the pipe get hot. | The whole end of the pipe and fitting get hot. |

Alignment Requirements | Needs less careful lining up; good for tricky or hard spots. | Needs the pipe and fitting ends lined up just right. |

Automation | Machines control the welding time and heat. | Can be done by hand or with some help from machines; skill matters. |

Equipment | Uses special, small welding machines that do not use much power. | Uses bigger machines with plates and clamps; needs more power. |

Suitable Pipe Sizes | Works better for small pipes and tricky shapes. | Works better for big pipes and long lines. |

Application Scenarios | Good for fixing, changing, tricky pipe joins, city gas, and drinking water pipes. | Good for big main pipes like water, sewage, and factory pipes. |

Joint Strength | Makes joints that are even stronger than the pipe. | Makes strong, solid joins that are also stronger than the pipe. |

Chemical & Pressure Resistance | Great at handling chemicals, high pressure, and stress from the ground. | Handles chemicals and heat very well. |

Installation | Quick and easy to put in with machine help. | Needs more skill and careful work to put in. |

Many jobs use electrofusion fittings to make safe, strong pipe joins.

Electrofusion is important for joining water polyethylene pipes. Workers use these fittings in gas lines, water pipes, and factories. The fittings make strong, leak-free joins that meet tough safety rules.

Some usual uses are:

Pipes that move natural gas and propane

City water pipes

Gas pipes and chemical plants in factories

Fire safety pipes

Pipes in mines and landfills

Pipes for watering and plumbing

Electrofusion couplings and other types, like reducers and transition fittings, help join pipes of different sizes or materials. The way the electrofusion fitting attaches makes sure each join can handle pressure and tough conditions.

Note: Electrofusion fittings are very helpful for pipes underground and in places where safety and strength are most important.

The electrofusion process creates a strong and reliable connection between polyethylene pipes. This joining process uses special fittings with embedded heating coils. A control unit manages the heat and timing. The steps below explain how to achieve a safe and durable joint.

Proper preparation is the most important part of the electrofusion process. Clean and well-prepared surfaces help the pipes bond at the molecular level. Follow these steps for best results:

Clean the pipe and fitting surfaces with water and a mild detergent. Remove all mud, dust, grease, or other impurities. Do not use harsh solvents like gasoline.

Cut the pipe ends straight and flat using the right cutters. Deburr and chamfer the edges if needed.

Mark the area to be scraped on at least one-third of the pipe’s circumference. Extend this area at least 10 mm beyond the fitting’s insertion depth.

Remove the oxidized layer from the pipe using a scraper. Do not use sandpaper. For pipes up to 63 mm, scrape about 0.1 mm deep. For larger pipes, scrape about 0.2 mm.

Clean the scraped area again with detergent. Make sure the surface is dry. Keep the fitting in its packaging until just before use.

Mark the insertion depth on the pipe. This mark should match half the length of the fitting.

Insert the pipes into the fitting gently. Use aligners to keep everything straight. If the pipe does not fit, check the diameter and shape.

Tip: Always scrape and clean the pipe right before fusion. Even small amounts of dirt or oil can weaken the joint. Industry experts say that skipping cleaning steps is a common cause of joint failure.

The fusion step uses the heating coils inside the electrofusion fitting. The control unit sends electricity through the coils. The coils heat up and melt the inside of the fitting and the outside of the pipe. This creates a strong bond as the materials mix together.

The control unit reads a barcode on the fitting. This barcode tells the machine how much heat and time to use.

The machine starts the fusion cycle. It keeps the temperature and timing exact.

After heating, the machine stops. The joint must cool down naturally. Do not move or stress the pipes during cooling. This helps the joint become strong and leak-proof.

The electrofusion process works well in tight spaces and for repairs. It does not need large machines or open pipe ends. In comparison, butt fusion methods like those used with FusingX Butt Fusion Fittings require heating both pipe ends with a hot plate and pressing them together. Butt fusion works best for large, straight pipes and long runs. Electrofusion is better for small pipes, repairs, or places where space is limited.

Inspecting the joint ensures the electrofusion process worked correctly. Modern technology uses ultrasonic array imaging to check the joint. This method sends sound waves through the joint and creates a picture of the inside.

Inspectors can see the heating wires, the length of the fused area, and any cold spots.

The system can find defects like voids, poor fusion, or trapped dirt.

This inspection is fast and does not damage the pipe. It works before the pipe is used and during service.

Cause of Failure | Explanation |

|---|---|

Improper Surface Preparation | Not removing the outer layer or lubricants can weaken the joint. |

Contamination on Fusion Interface | Dirt, dust, or oil on the surfaces can cause leaks or weak spots. |

Misalignment of Pipes | Pipes that are not straight may not bond well. |

Strain from Backfilling or Instability | Moving or stressing the pipe before the joint cools can cause failure. |

Hydrocarbon Permeation | Chemicals in the soil can enter the pipe wall and weaken the joint. |

Environmental Conditions | Cold or wet weather can affect how well the joint forms. |

Note: Careful inspection and following all steps help prevent these common problems. Proper training and the right tools make a big difference in the quality of the electrofusion joint.

Electrofusion joints make pipes stick together very well. The process melts the pipe and fitting so they join tightly. This makes a bond as strong as the pipe. The joint does not use gaskets or bolts. This means there are fewer weak spots. It helps stop leaks from happening. The inside of the joint is smooth. This keeps water and other fluids clean. It stops biofilm from growing inside. Electrofusion joints do not rust or get damaged by chemicals. They can handle hot and cold temperatures. They also hold up under high pressure and heavy weight. These things make electrofusion a great choice for pipelines that last a long time.

Tip: Electrofusion joints do not need repairs and do not leak. This saves money on fixing pipes later.

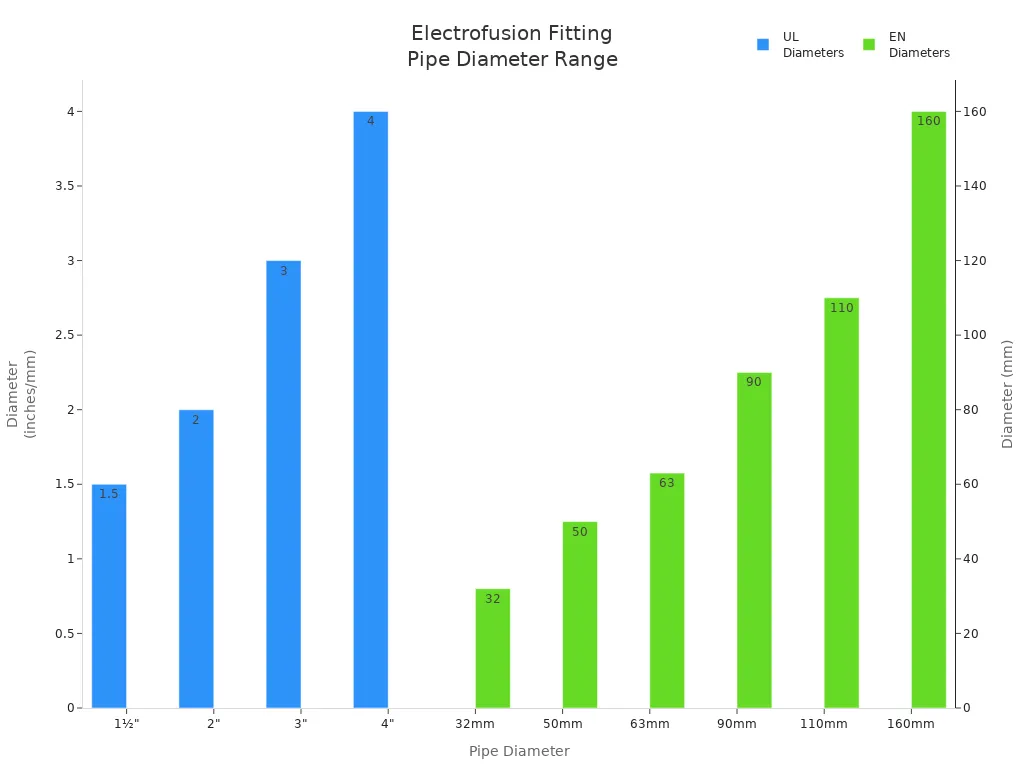

Electrofusion fittings work with many pipe sizes and types. They fit small pipes and big pipes. This makes them good for many kinds of jobs. The table below shows what sizes and uses they support:

Aspect | Details |

|---|---|

Supported Pipe Diameters (UL) | 1½", 2", 3", 4" |

Supported Pipe Diameters (EN) | 32mm, 50mm, 63mm, 90mm, 110mm, 160mm |

Welder Capability | Automatically calculates welding settings for any pipe size or type |

Suitable Applications | Product lines, vent lines, vapor lines, above and below ground |

Pipework Flexibility | Semi-rigid for vent lines, flexible for product lines |

Gemini™ Secondary Containment | Two-piece design for complex layouts |

Makers create electrofusion fittings in many sizes. They go from 1/2 inch up to 63 inches (2000mm). These products meet rules from different countries. This shows they work for many projects and places.

Electrofusion fittings help keep pipes safe. They follow tough rules like ISO 4427, ISO 4437, EN 12201, and EN 1555. These rules make sure the fittings can handle stress, pressure, and heat or cold. The joint does not let leaks happen. It also keeps dirt and germs out. The material is not metal, so it does not rust. It does not react with chemicals. This keeps water, gas, and other fluids safe as they move through pipes. Electrofusion fittings work well in hard places like mines, offshore sites, and far-away areas. Their strong build and careful steps during installation protect people and nature.

To install electrofusion fittings well, you need the right tools. Installers use a fusion control unit. This unit checks the heat and time during fusion. It helps make a strong and safe joint. Workers also use scrapers, clamps, and lint-free wipes. These tools clean the pipe and take off any dirt or old layers. If the pipe is not clean, the joint can be weak. It is important for everyone to learn how to use these tools.

Equipment Type | Upfront Cost Description | Additional Notes on Cost and Productivity |

|---|---|---|

Electrofusion Equipment | Higher initial cost including machine and parts | Requires training; can reduce future repair and downtime costs |

Manual Butt Fusion Equipment | Lower upfront cost, good for smaller projects | Operator-dependent, lower throughput |

Automatic Butt Fusion Equipment | Higher upfront cost than manual, lower long-term costs | Increases productivity, reduces labor costs |

There are some problems that can happen when installing electrofusion fittings.

If clamps are not used right, pipes may not line up and joints can be weak.

If the equipment is not set right, the heating can be wrong and the joint will not be strong.

If you move the joint before it cools, it can crack.

Dirty welding surfaces make the joint less strong.

Very hot or cold weather and wet pipes can hurt the weld.

If workers do not have enough training, mistakes happen more often.

High starting costs, trouble getting supplies, and fake parts can also cause issues.

Workers must keep welding surfaces free from dirt and pollution. Pipes should not be in water while being joined. In places where it gets very hot or cold, special tools help stop pipes from moving too much. Pipes must not move while cooling so the joint stays strong.

Good training helps workers do every step right, like cleaning and lining up pipes. Even the best fittings will not work if the job is done badly.

Some things in the environment or the pipe can make electrofusion harder. Bentonite slurry from drilling can cover pipes and stop them from bonding. Scratches or cuts in the fusion area can trap dirt and make the joint weak. After pulling pipes, HDPE pipes need time to rest before joining. Pipes that are bent or under stress can break the joint. For big pipes or long, straight lines, butt fusion fittings like FusingX may be a better choice for a strong join.

Electrofusion fittings make joints that do not leak. These joints help keep water, gas, and factory systems safe. The fittings last a long time and do not rust. They are easy to put in, so many people use them for different jobs.

They fit well in small spaces and tough places.

Butt fusion works better for big, straight pipes.

The best choice depends on the job, tools, and worker skills.

Talking to experts or companies like FusingX helps you pick the right fittings for your pipes.

Electrofusion fittings make joints that do not leak. They are strong and last a long time. Installers use them in small or tight places. These fittings work for water, gas, and chemical pipes. They do not rust and stay safe for years. Many industries use them because they are reliable.

Electrofusion has heating coils inside the fitting. A control unit sets the heat and time. Butt fusion uses a hot plate to heat pipe ends. Then, the ends are pressed together. Electrofusion is better for repairs and small spaces. Butt fusion works best for big, straight pipes.

Only trained workers should put in electrofusion fittings. The job needs special tools and clean pipes. Training helps workers avoid mistakes. Many companies teach people how to do this. Good installation makes joints strong and pipes safe.

Electrofusion fittings join HDPE and MDPE pipes. They fit many sizes and shapes. Installers use them for water, gas, and factory pipes. These fittings follow strict safety rules.

Butt fusion fittings are best for big pipes and long, straight lines. Projects needing strong and tough joints use butt fusion. FusingX has many butt fusion fittings for these jobs.