close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Polyethylene pipe fittings are important in today’s piping systems. There are many types of fittings for high-density polyethylene pipes. The most common ones are butt fusion fittings. These make strong and lasting joints. Electrofusion fittings use wires inside to join pipes well. Compression fittings help you install pipes quickly. You can also find stub ends and flange adaptors. Fabricated fittings and insert fittings are used for special jobs or custom needs. People use pe pipe fittings for water, gas, or factories. These fittings are tough and can be used in many ways. You might ask how much polyethylene fittings cost for your job. FusingX has many pe pipe types and custom choices for different needs.

Butt fusion fittings

Electrofusion fittings

Compression fittings

Stub ends and flange adaptors

Fabricated fittings

Insert fittings

Polyethylene pipe fittings have many types. These include butt fusion, electrofusion, compression, threaded, and flanged fittings. Each type works best for different jobs and pressures.

Joining methods like compression, electrofusion, and butt fusion make strong joints. These joints do not leak. Pick the method that matches your project and tools.

Polyethylene fittings are used for water, gas, drainage, and industrial systems. They are strong and flexible. They do not rust or break easily.

Always match the fitting size, pressure rating, and material to your pipe. Also match them to your environment. This helps keep connections safe and long-lasting.

Custom fittings help with special installation problems. They also make unique projects work better.

Compression fittings let you join pipes fast and easy. You do not need heat or special tools for this. Just twist a nut to squeeze a ring on the pipe. This makes a tight seal. These pipe fittings are good for low-pressure water and irrigation. You can take them apart and put them back together without trouble.

Tip: Compression fittings work well when you want a quick and easy connection.

Advantages of Compression Fittings |

|---|

Strong, leak-free seal |

No heat or soldering needed |

Simple to put in and take out |

Electrofusion fittings have wires inside to join pipes. When you use electricity, the wires melt the fitting onto the pipe. This makes a strong, leak-proof joint. People use these polyethylene fittings for gas and water pipes. They work above or below ground and help keep things safe.

Electrofusion fittings are simple to use and save time.

They stand up to chemicals and last many years.

Butt fusion fittings join pipes by heating their ends and pressing them together. This makes a strong, smooth joint. You use these pipe fittings for water, gas, and factories. They do not rust and have a smooth inside, so water moves easily.

Butt fusion fittings follow strict rules for safety and strength.

They come in many shapes like elbows, tees, and reducers.

Threaded fittings have grooves so you can screw pipes together. You can use them to join polyethylene pipe fittings to metal or other pipes. These pipe fittings are easy to put in and take out. They work best for low pressure or when you need to take pipes apart often.

Flanged fittings use flat rings with holes for bolts. You bolt two flanges together to join pipes or connect to pumps and valves. These pipe fittings are strong and easy to take apart for fixing. Flanged fittings are common in big water or factory systems.

Feature | Flanged Fittings |

|---|---|

Installation | Needs bolts and lining up |

Cost | Higher because of size and work |

Siphonic drainage fittings help move rainwater from roofs fast. Their special shape keeps air out and lets water flow quickly under pressure. These polyethylene fittings use fusion welding for tight seals. They are strong, bendy, and last over 50 years.

Siphonic drainage fittings handle lots of water and can move with buildings.

Sometimes you need special polyethylene pipe fittings for unique jobs. Custom and specialty pipe fittings fit big pipes, small spaces, or odd angles. FusingX makes custom fittings to fit your needs. These pipe fittings meet high standards and work for water, gas, and factories.

Note: FusingX has pe pipe fittings from 20mm to 1200mm, made from strong PE100. You can use them for water, gas, farms, and factories. Heat fusion saddles and other fittings are also ready for special jobs.

When you use polyethylene pipe fittings, you must join them the right way. Each joining method has its own steps and tools. Some methods work better for certain jobs. FusingX makes pipe fittings that work with all these joining ways. You can pick what works best for your project.

The compression method is fast and simple. You do not need heat or special tools. Just slide the pipe into the fitting and twist a nut. The ring inside squeezes the pipe to make a seal. You can take these pipe fittings apart and use them again. This method is good for low-pressure water and irrigation.

Joining Method | Description | Advantages |

|---|---|---|

Compression Fittings | Use compression to seal around the pipe; no special tools needed. | Easy to put in and take out; good for low pressure; works in many places. |

Electrofusion fittings use electricity to join pipes. First, clean the pipe ends and scrape off the top layer. Mark how deep the pipe goes in. Put the pipe into the fitting. Use a special machine to send current through wires inside. The wires get hot and melt the plastic. This fuses the pipe and fitting together. You get a strong, leak-proof joint. This method works in small spaces and for high or low pressure. FusingX has good electrofusion fittings for water, gas, and factories.

Tip: Always clean and scrape the pipe ends before using electrofusion. This helps you get a safe and strong joint.

Steps for a good electrofusion joint:

Clean pipe and fitting with water and soap.

Cut pipe ends flat.

Mark where to scrape.

Scrape off the old layer.

Clean again and dry.

Mark how deep to insert.

Put pipe in and line it up.

The butt fusion method makes strong, lasting joints. You heat the ends of the pipes and press them together. The melted plastic cools and forms a smooth weld. This method is best for high-pressure water and gas. FusingX makes butt fusion fittings and heat fusion saddles that are very safe.

Joining Method | Description | Advantages |

|---|---|---|

Butt Fusion | Pipes are heated and pressed together to form a seamless, welded joint. | Makes strong, lasting, leak-free joints; best for high pressure. |

Threaded connections let you screw pipe fittings together. You can join polyethylene pipe fittings to metal pipes or valves. Flanged connections use bolts and rings to connect pipes to pumps or other equipment. Both ways make it easy to take pipes apart for fixing. These joining methods are good when you need to disconnect pipes often.

Joining Method | Description | Advantages |

|---|---|---|

Threaded | Threaded adapters connect PE pipes to metal pipes or valves. | Secure connection between different materials; easy to put in and take out; works in many ways. |

Flanged | Flanges are bolted to connect PE pipes to equipment or other pipes. | Good for high pressure; easy to fix and take apart. |

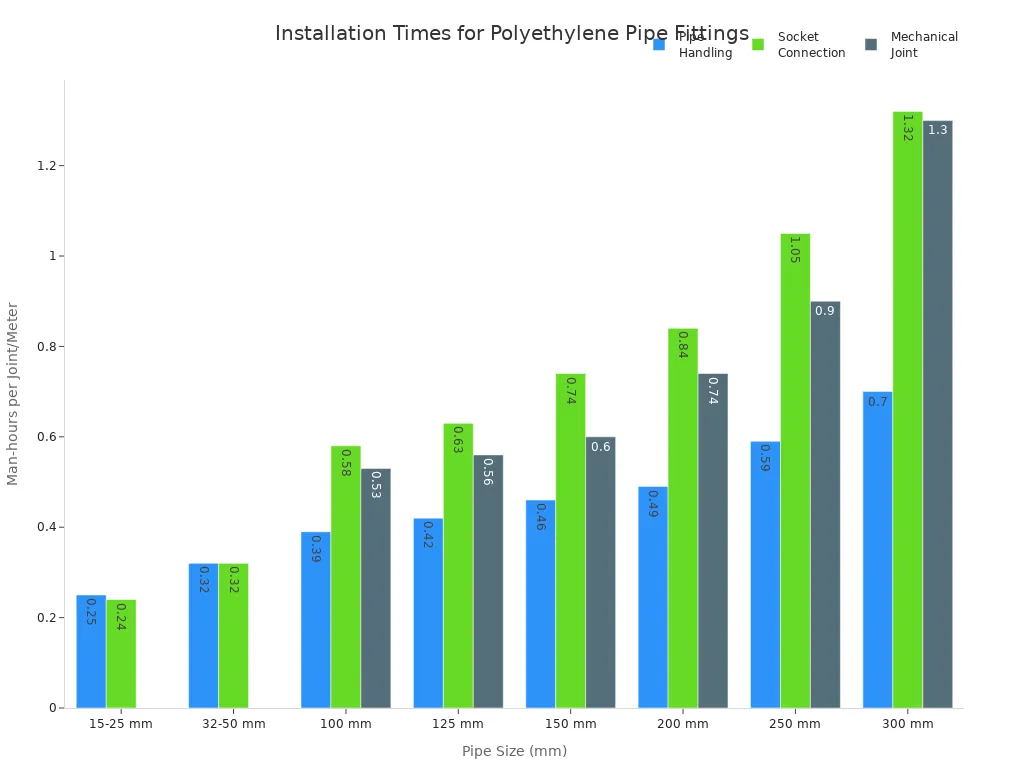

You should know that each joining method takes a different amount of time and work. Simple ways like compression and socket connections are faster. Mechanical joints and fusion welding need more skill and time, especially for big pipes.

FusingX gives you many ways to join polyethylene pipe fittings. You can choose the method that fits your project, money, and pressure needs.

Polyethylene fittings are used in many water systems. They work in city water, building water, and farm irrigation. You also see them in homes and factories. People pick these fittings because they are light and bend easily. They do not break down from chemicals. They make tight joints that do not leak. These fittings can last as long as 50 years. You can join PE pipes to other pipes with special connectors. This makes them good for many kinds of water jobs.

Tip: Polyethylene fittings help you build water systems that last long and need little fixing.

Polyethylene fittings are important for safe gas pipes. These fittings must follow strict safety rules. The government has strong rules for plastic gas pipes. Polyethylene pipes have higher safety factors now. The rules for fittings and joints are even tougher. Mechanical fittings must meet stronger standards. New rules guide how to use pipes and fittings. You must follow steps to join plastic pipes the right way. The rules help keep gas pipes safe. These rules started in 2019. You get safer gas pipes and better technology with these changes.

Safety Feature | Description |

|---|---|

Design Factors | Higher for added safety |

Fitting Standards | More strict for better reliability |

Installation Requirements | Make sure pipes are joined right |

Polyethylene fittings help move water fast in drains. Siphonic fittings take rainwater off roofs quickly. Their shape keeps air out and lets water move fast. Fusion welding makes tight seals that do not leak. These fittings last over 50 years and handle lots of water. You see them in big buildings and factories.

Polyethylene fittings are used in many factory and special jobs. HDPE fittings use butt fusion, electrofusion, and extrusion welding. These ways make strong joints that do not leak. Fittings made in a shop are better and faster to put in. Custom fittings help with hard jobs in boats, mines, landfills, and more. Polyethylene fittings are strong and do not break from hits, heat, or water. They are light and bendy, so they are easy to use. These fittings make tight joints and can last up to 100 years. You save money and get better pipes with custom fittings.

Note: Polyethylene fittings give you good answers for hard factory jobs.

When you choose pipe fittings, you need to think about how and where you will use them. Not all fittings work for every job. You should check if the fitting matches your pipe’s diameter, wall thickness, and pressure rating. HDPE pipe fittings work well for high-pressure and tough jobs because they are strong and resist corrosion. LDPE fittings fit low or medium pressure systems. You also need to look at the environment. Sunlight, soil, and temperature changes can affect your pipes. Some fittings, like electrofusion, work better in tight spaces or underground. Custom pipe fittings help when you have special shapes or sizes.

Make sure the fitting matches your pipe’s size and pressure needs.

Pick the right material for your job.

Think about where you will install the pipes.

Use custom fittings if standard ones do not fit.

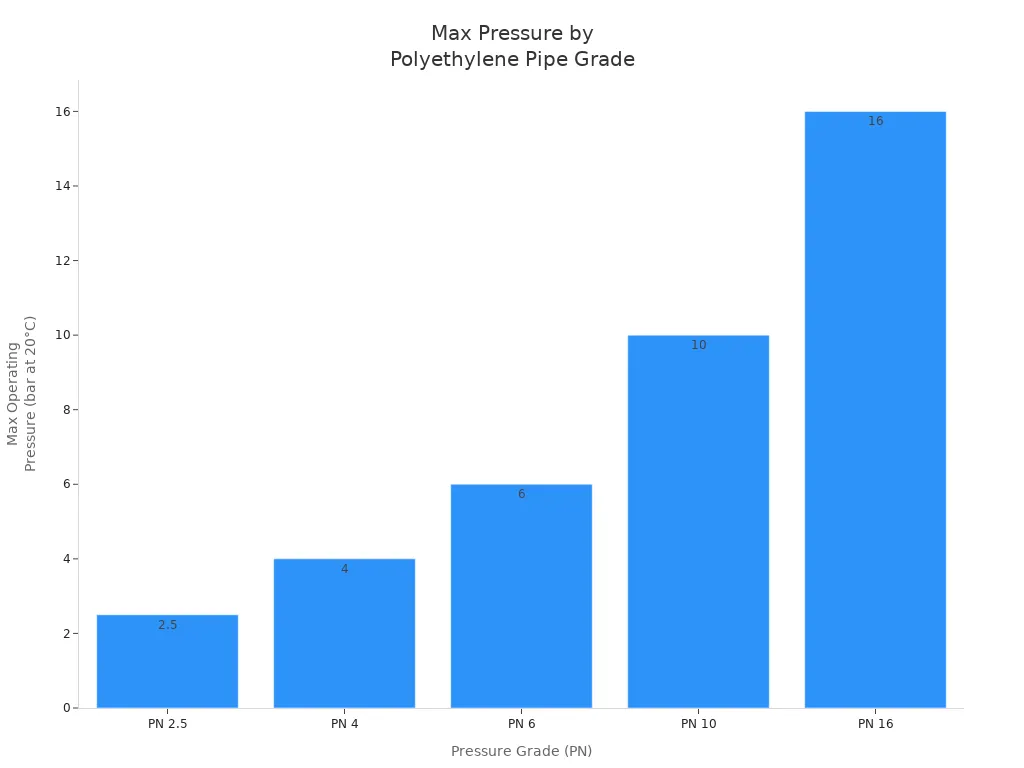

You must match the pressure grade and size of your pipe fittings to your system. The pressure grade tells you how much pressure the pipe can handle. The size must fit your pipe’s diameter and wall thickness. Here is a table to help you choose:

Pressure Grade (PN) | Max Pressure (bar at 20°C) | Material Type | Common Uses |

|---|---|---|---|

PN 2.5 | 2.5 | PE 32, PE 40 | Low pressure systems |

PN 4 | 4 | PE 63 | Irrigation, drinking water |

PN 6 | 6 | PE 63 | Medium pressure systems |

PN 10 | 10 | PE 80 | Drinking water, industry |

PN 16 | 16 | PE 80, PE 100 | Gas, high demand water lines |

Most HDPE pipe fittings come in sizes from 20 mm to 1,200 mm. Always check the color code on the pipe for its pressure grade.

You can make better choices by following a few simple tips:

Think about what you need the pipe fittings to do and the conditions they will face.

Learn about the different types, like compression, electrofusion, and butt fusion, and pick the best one for your project.

Always follow the manufacturer’s instructions for installing the fittings.

Make sure the fitting and pipe are made from materials that work well together.

Choose fittings that meet your technical and environmental needs for the best results.

If your project has special needs, companies like FusingX can make custom pipe fittings just for you. This helps you get the right fit and the best performance.

You can pick from many kinds of polyethylene pipe fittings. Each type and way to join them works for different jobs. To keep things safe and working well, you should:

Follow ASTM rules to make sure the fittings are good.

Make sure the pressure ratings and sizes match your pipes.

Use the right ways to put in the fittings and check their labels.

Watch out for pipes getting longer or shorter with heat and use supports if needed.

Both regular and special fittings, like the ones from FusingX, help you make strong systems. If your project is big or tricky, talk to experts so you get the best results.

Butt fusion fittings join pipes by heating their ends. Then, you press the ends together to make a joint. Electrofusion fittings have wires inside that melt the pipe. The wires use electricity to fuse the pipe and fitting. You pick the method based on your project and tools.

You can reuse compression fittings if they look good. Threaded fittings can also be used again. Fusion fittings make joints that last forever. You cannot reuse butt fusion or electrofusion fittings after you put them in.

You need to match the fitting size to your pipe’s outside diameter. Always check the label on the pipe or measure it first. Picking the right size helps you get a tight and leak-free fit.

Yes, most polyethylene fittings use food-grade PE100 material. These fittings do not rust and keep water clean. They do not change how water tastes. Always look for certifications before you use them.

You use custom fittings for special shapes or small spaces. They work for unique jobs. FusingX makes custom fittings for water, gas, factories, and farms.