close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

Several types of HDPE elbows exist, each designed for specific pipe systems and project demands. The Pros and cons of different HDPE elbow types often surprise industry professionals. Careful evaluation of these differences helps ensure the right choice for performance, safety, and cost-effectiveness. Some benefits or drawbacks may not be immediately obvious but can greatly impact long-term results.

Different types of HDPE elbows exist, each designed for specific applications and project needs.

Injection-molded elbows offer consistent quality and are ideal for high-pressure systems due to their toughness and chemical resistance.

Fabricated elbows provide flexibility for custom angles and larger diameters, making them suitable for unique project requirements.

Segmented elbows allow for easy adjustments in pipeline direction, making them perfect for complex layouts and tight spaces.

Electrofusion elbows create strong, leak-proof bonds and are ideal for critical infrastructure projects requiring precision.

Compression elbows simplify installation with no special tools needed, making them great for quick repairs and temporary setups.

Threaded elbows are perfect for systems needing frequent disassembly, offering secure connections and easy maintenance.

Choosing the right HDPE elbow type can enhance performance, reduce costs, and ensure long-term reliability in piping systems.

Injection-molded elbows represent one of the most common types of hdpe pipe elbows in modern piping systems. Manufacturers use a precise process where hdpe resin pellets are heated, melted, and injected into specialized molds under high pressure. This method ensures consistent wall thickness and dimensional accuracy for each elbow. The cooling rate is carefully managed to prevent warping or cracking, which can compromise the integrity of the fitting. Each step in the process is controlled to meet international standards such as ASTM D3261 and ASTM F2206.

These hdpe pipe elbows are known for their toughness and chemical resistance. The material’s melting temperature ranges from 180°C to 230°C, which allows the elbows to perform reliably in demanding environments. Injection-molded elbows are widely used in municipal water supply, gas distribution, and industrial applications. Their leak-proof design and robust construction make them a preferred choice for high-pressure systems, especially when paired with a butt fusion elbow or socket fusion elbow.

Tip: Injection-molded hdpe pipe elbows offer excellent repeatability and quality, making them ideal for projects that require large quantities of identical fittings.

Fabricated elbows are produced by cutting and welding sections of hdpe pipe to create the desired angle. This method allows for greater flexibility in manufacturing, as it can accommodate custom angles and larger diameters not possible with standard injection molding. Fabricated hdpe pipe elbows are often used in projects where unique configurations or non-standard sizes are required.

The fabrication process involves precise cutting, alignment, and butt fusion welding of pipe segments. This technique ensures strong, seamless joints that maintain the mechanical properties of the original hdpe material. Fabricated elbows are suitable for both above-ground and buried installations. They are commonly found in water treatment plants, industrial facilities, and large-scale infrastructure projects.

Note: Fabricated hdpe pipe elbows can be tailored to meet specific project requirements, offering a solution when standard fittings are not available.

Segmented elbows are constructed from multiple pieces of hdpe pipe, joined together to form bends of various angles. This approach provides exceptional adaptability for complex pipeline layouts. Segmented hdpe pipe elbows are available as 45-degree, 90-degree, or custom angle fittings, making them suitable for navigating around obstacles or fitting into tight spaces.

The segmented design allows for easy adjustments in pipeline direction during installation. These elbows are lightweight, which reduces labor costs and installation time. They also offer high resistance to corrosion, UV exposure, and chemical degradation, ensuring a long service life. Fusion welding techniques used in assembly create leak-free joints, enhancing the reliability of the system.

Type of Fitting | Description | Common Applications |

|---|---|---|

45-Degree Bend Fittings | Moderate change in direction for gentle curves. | Navigating around obstacles or tight spaces. |

90-Degree Bend Fittings | Right-angle change in direction. | Redirecting flow or connecting perpendicular pipelines. |

Custom Angle Bend Fittings | Fabricated to meet specific angle requirements. | Unique project requirements and site conditions. |

Segmented Bend Fittings | Multiple pieces for adjustable angles. | Flexible adaptation to various layouts and scenarios. |

Segmented hdpe pipe elbows are frequently used in municipal, industrial, and agricultural applications. Their flexibility and durability make them a reliable choice for challenging installation environments.

Electrofusion elbows represent a modern solution for connecting hdpe pipe elbows in critical infrastructure projects. These fittings use embedded heating coils that, when energized, melt the hdpe material at the joint, creating a strong and leak-proof bond. This method ensures high precision and repeatability, which is essential for municipal water supply, gas distribution, and industrial applications. XFusing’s electrofusion hdpe pipe elbows are engineered for reliability and ease of use, making them suitable for both new installations and repairs.

The installation process for electrofusion elbows requires careful preparation. The pipe ends must be cut perpendicular and flat. A professional scraper removes the oxidized layer from the insertion area, ensuring a clean surface for welding. The pipe is then inserted into the fitting to the marked depth, and the electrofusion welding machine is connected. After the welding cycle, the joint must cool naturally before pressure testing.

Tip: Electrofusion hdpe pipe elbows are automation-friendly and compatible with a wide range of pipe sizes, making them ideal for projects that demand efficiency and accuracy.

Key Features | Installation Requirements |

|---|---|

Precision Engineering | Ensure the hdpe pipe end face is perpendicular and flat. |

Embedded Heating Coils | Use a professional scraper to thoroughly scrape the insertion area. |

Versatile Designs | Insert the pipe into the fitting to the marked depth, ensuring proper alignment. |

Compatibility | Securely connect the electrofusion welding machine to the fitting. |

Automation-Friendly | Allow the pipes to cool naturally after welding and conduct a pressure test before use. |

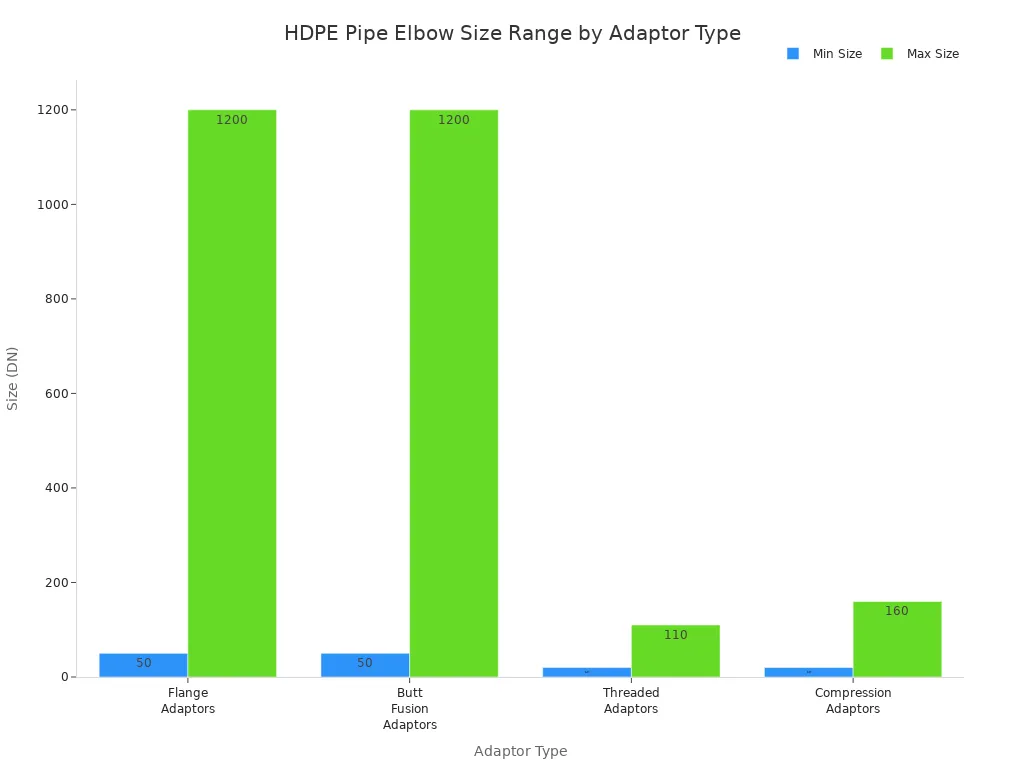

Compression hdpe pipe elbows offer a practical solution for quick and easy assembly, especially in small to medium-sized systems. These fittings use a mechanical compression mechanism to create a tight seal between the pipe and the fitting. No special tools or welding equipment are required, which reduces installation time and labor costs. XFusing’s compression hdpe pipe elbows are designed for versatility and can be used in municipal, agricultural, and residential applications.

Compression elbows are best suited for pipes under 4 inches (110mm) in diameter. Their ease of use makes them accessible for workers with varying skill levels. These hdpe pipe elbows are ideal for temporary installations, system modifications, or emergency repairs.

Use Case | Description |

|---|---|

Smaller Diameters | Compression fittings are ideal for pipes under 4 inches (110mm). |

Ease of Use | They can be installed without special equipment, making them accessible for workers. |

Note: Compression hdpe pipe elbows provide flexibility and speed, making them a preferred choice for projects with tight deadlines.

Threaded hdpe pipe elbows are designed for systems that require frequent disassembly or reconfiguration. These fittings feature precision-cut threads that allow for secure, leak-resistant connections. Threaded elbows are commonly used in industrial, marine, and irrigation systems where maintenance or system changes are expected.

XFusing’s threaded hdpe pipe elbows are manufactured to meet international standards, ensuring durability and compatibility with other threaded components. Their robust construction and chemical resistance make them suitable for harsh environments. These hdpe pipe elbows are available in a variety of sizes, supporting a wide range of pipe diameters and application scenarios.

Tip: Threaded hdpe pipe elbows are ideal for installations where future modifications or expansions are anticipated.

Injection-molded hdpe pipe elbows deliver a range of benefits that make them a preferred choice in many industries. Their manufacturing process ensures consistent quality and dimensional accuracy, which is critical for reliable pipe systems. The following table summarizes the main advantages:

Advantage | Description |

|---|---|

Chemical Resistance | HDPE resists a wide range of chemicals, including strong acids and bases, making it reliable in chemical-heavy environments. |

Cost Efficiency | It is cost-efficient compared to specialty plastics, with fast cycle times reducing production costs. |

Durability and Strength | High tensile strength (20–40 MPa) and impact resistance ensure longevity in harsh conditions. |

Lightweight | Low density (0.94–0.97 g/cm³) reduces shipping costs and material use. |

Recyclability | Fully recyclable, supporting sustainable manufacturing practices. |

Versatility in Design | Supports complex shapes and features, enhancing design flexibility. |

Weather and UV Resistance | With UV additives, it resists degradation, ideal for outdoor applications. |

FDA Compliance | Meets FDA standards for safe use in food packaging and medical devices. |

These elbows are suitable for a wide range of applications, from municipal water supply to industrial chemical transport. Their lightweight nature simplifies handling and installation, while their recyclability supports sustainability goals. The pros and cons of different hdpe elbow types often highlight the versatility and reliability of injection-molded options.

Despite their strengths, injection-molded hdpe pipe elbows have some limitations. The table below outlines the most notable disadvantages:

Disadvantage | Description |

|---|---|

Limited Heat Resistance | Softens above 120°C, limiting use in high-temperature applications. |

Susceptibility to Stress Cracking | Prolonged exposure to chemicals can cause environmental stress cracking. |

Post-Processing Needs | Some parts require additional treatments, increasing costs. |

High Thermal Expansion | High thermal expansion coefficient necessitates precise mold tolerances. |

Flammable | Requires flame-retardant additives for fire-prone applications. |

Difficult to Bond | Low surface energy hinders adhesive bonding, limiting multi-material applications. |

Unexpected disadvantages can include the need for post-processing or the challenge of bonding with other materials. These factors should be considered when evaluating the advantages and disadvantages of hdpe pipe elbows for specific projects.

Fabricated hdpe pipe elbows offer unique benefits, especially for custom or large-diameter installations. The fabrication process allows for the creation of non-standard angles and sizes, which is essential for complex pipeline layouts. These elbows maintain the mechanical properties of hdpe, ensuring durability and resistance to impact. Fabricated elbows are also compatible with various joining methods, including butt fusion, which provides strong, leak-proof connections. Their adaptability makes them valuable in water treatment plants, industrial facilities, and infrastructure projects where standard fittings may not suffice.

Tip: Fabricated elbows can be tailored to meet unique project requirements, providing flexibility that injection-molded options cannot match.

While fabricated hdpe pipe elbows excel in customization, they may require more time and skilled labor for production and installation. The joining process, such as butt fusion welding, demands precise alignment and quality control to ensure joint integrity. In some cases, the cost can be higher due to the additional fabrication steps. However, for projects with complex routing or large diameters, the pros and cons of different hdpe elbow types often favor fabricated solutions for their versatility.

Segmented hdpe pipe elbows stand out for their adaptability and performance in challenging environments. These elbows are constructed from multiple pipe segments, allowing for custom angles and configurations. Key advantages include:

Excellent resistance to chemicals, corrosion, and UV radiation, making them suitable for outdoor and industrial use.

The segmented welding process enhances structural integrity, ensuring reliable connections under high pressures and temperature fluctuations.

Made of inert materials, segmented elbows provide good corrosion resistance to galvanic corrosion, electrical currents, salts, acids, and water vapor.

Immediate usability without the need for anti-corrosion treatment.

The pros and cons of different hdpe elbow types often reveal that segmented elbows excel in scenarios where flexibility and durability are critical.

Segmented hdpe pipe elbows may require more complex assembly compared to other types. The process involves multiple fusion welds, which can increase installation time and require skilled technicians. In addition, precise alignment is necessary to maintain flow efficiency and prevent leaks. Despite these challenges, the advantages and disadvantages of segmented elbows make them a strong choice for pipelines with unique routing needs.

The pros and cons of different hdpe elbow types should always be weighed against the specific requirements of the pipe system, application environment, and long-term maintenance expectations.

Electrofusion elbows offer advanced solutions for modern pipe systems. These fittings use embedded heating elements to create strong, uniform joints. The process ensures a reliable connection between each pipe and elbow, even in demanding environments.

High joint integrity. Electrofusion creates a homogenous bond that matches the strength of the original hdpe material.

Leak-proof performance. The fusion process eliminates gaps, reducing the risk of leaks in water and gas distribution systems.

Minimal installation space. Electrofusion elbows require less room for assembly compared to traditional methods, making them ideal for confined spaces.

Automation compatibility. The process supports automated welding, which increases consistency and reduces human error.

Wide application range. These elbows work well in municipal, industrial, and repair projects, especially where precise alignment is critical.

Compliance with international standards. XFusing’s electrofusion fittings meet ISO4427 and ASTM D3261 requirements, ensuring safety and reliability.

Tip: Electrofusion elbows are suitable for both new installations and system upgrades, offering flexibility for future expansion.

While electrofusion elbows provide many benefits, some challenges may arise during installation and operation.

Specialized equipment required. The process needs an electrofusion welding machine and trained personnel.

Preparation sensitivity. Pipe ends must be clean and properly aligned to achieve a strong bond.

Cooling time. Joints require a set cooling period before pressure testing or use.

Power supply dependency. Electrofusion welding relies on a stable electrical source, which may not be available in remote locations.

Unexpected factors, such as the need for precise surface preparation, can impact project timelines. However, when installed correctly, electrofusion elbows deliver long-term performance and durability.

Compression elbows provide a practical and efficient solution for connecting hdpe pipe in small to medium-sized systems. These fittings use a mechanical compression mechanism, which simplifies installation and maintenance.

Quick assembly. Compression elbows do not require welding or special tools, reducing labor costs and installation time.

Reusability. These fittings can be disassembled and reused, making them ideal for temporary or adjustable systems.

Versatility. Compression elbows accommodate a range of pipe diameters and are suitable for municipal, agricultural, and residential applications.

Strong sealing. The compression mechanism creates a tight, leak-resistant seal, minimizing water loss and environmental contamination.

Lightweight design. The low weight of hdpe reduces transportation costs and energy consumption.

Sustainability. Compression elbows support recyclability and promote a circular economy. Their long service life reduces the need for frequent replacements.

Chemical resistance. These fittings handle corrosive fluids without degradation, making them suitable for diverse environments.

Energy efficiency. Manufacturing and installing compression elbows require less energy compared to metal alternatives.

Note: Compression elbows help conserve water and reduce waste, supporting sustainable infrastructure development.

Compression elbows, while convenient, have some limitations that should be considered.

Limited pressure rating. These fittings are best suited for low to medium-pressure pipe systems.

Size restrictions. Compression elbows typically accommodate pipes up to 110mm in diameter.

Periodic inspection. Mechanical seals may require occasional tightening or replacement to maintain leak-free performance.

Despite these factors, compression elbows remain a preferred choice for projects that demand speed, flexibility, and sustainability.

Threaded elbows offer a reliable solution for pipe systems that require frequent disassembly or reconfiguration. These fittings feature precision-cut threads, ensuring secure and leak-resistant connections.

Standard/Certification | Description |

|---|---|

CMA | Third-party testing by qualified institutions, recognized internationally. |

NSF | Hygienic safety assessment for drinking water pipes to ensure no harmful substances leach. |

Easy installation and removal. Threaded elbows allow for quick changes without specialized tools.

Compatibility. These fittings connect seamlessly with other threaded components in industrial, marine, and irrigation systems.

Durability. Manufactured from high-quality hdpe, threaded elbows resist corrosion and chemical attack.

Compliance. XFusing’s threaded elbows meet international and local standards, including ASTM D2513, ASTM F2620, NFPA 54, API RP 15S, CSA Z662, and ISO 4437.

Maintenance-friendly. Threaded connections simplify routine inspections and repairs.

Tip: Threaded elbows are ideal for systems that require regular maintenance or future expansion.

Threaded elbows, while versatile, present some challenges in certain applications.

Pressure limitations. Threaded connections may not be suitable for high-pressure pipe systems.

Potential for leaks. Over-tightening or improper installation can damage threads and compromise the seal.

Size constraints. Threaded elbows are most effective in small to medium-diameter pipe systems.

Proper installation and adherence to standards ensure that threaded elbows deliver reliable performance in a variety of settings.

Cost is a primary consideration when selecting the right pipe fitting for any project. The price of each type of HDPE pipe elbow varies based on manufacturing method, size, and application. Injection-molded elbows typically offer the lowest cost for standard sizes due to efficient mass production. Fabricated and segmented elbows often cost more because they require additional labor and customization. Electrofusion and compression elbows fall in the mid-range, reflecting the value of specialized features and ease of installation. Threaded elbows are generally affordable for small diameters but can become expensive as size increases.

The following table summarizes the typical price range for HDPE 90-degree elbows, which are among the most commonly used fittings:

Type of Elbow | Price Range (USD) |

|---|---|

HDPE 90 Degree Elbows | 0.50 - 100.00 |

Project budgets benefit from understanding these cost differences. For large-scale municipal or industrial installations, selecting the right pipe fitting can lead to significant savings. XFusing’s product line covers a wide range of price points, ensuring options for both cost-sensitive and high-performance applications.

Durability determines the long-term value of any pipe system. HDPE elbows are known for their exceptional resistance to corrosion, chemicals, and environmental stress. Injection-molded and electrofusion elbows provide consistent wall thickness and robust joints, resulting in a service life that often exceeds 50 years under normal conditions. Fabricated and segmented elbows maintain the mechanical properties of the original pipe material, offering reliable performance even in demanding environments.

Compression and threaded elbows also deliver strong durability, especially when manufactured from 100% virgin PE100 material. This high-grade material resists cracking, abrasion, and UV degradation. XFusing’s fittings comply with international standards, ensuring that each pipe connection remains secure and leak-free over decades of use.

Note: Durability is not only about material strength but also about resistance to external factors such as soil movement, temperature changes, and chemical exposure.

Installation efficiency impacts project timelines and labor costs. Injection-molded elbows are straightforward to install, especially in systems that use butt fusion welding. Electrofusion elbows require specialized equipment but offer precise, repeatable joints with minimal risk of leaks. Compression elbows stand out for their tool-free assembly, making them ideal for quick repairs or temporary pipe systems.

Fabricated and segmented elbows may require more time and skilled labor due to the need for precise alignment and multiple fusion welds. Threaded elbows are easy to install and remove, which is beneficial for systems that require frequent maintenance or reconfiguration.

XFusing’s HDPE pipe fittings are designed for compatibility and ease of use. The wide size range, from DN50mm to DN800mm, supports diverse installation scenarios. Whether the project involves municipal water supply, gas distribution, or agricultural irrigation, choosing the right installation method ensures long-term system reliability.

Tip: Proper training and adherence to installation guidelines maximize the performance and lifespan of every pipe system.

Flexibility is a defining characteristic of modern pipe systems, especially in applications where ground movement or temperature fluctuations are common. HDPE fittings demonstrate significant flexibility, which allows them to absorb stress and impact without cracking or failing. This property is essential for municipal water supply, gas distribution, and industrial installations.

Property | Description |

|---|---|

Flexibility | HDPE fittings can bend and adapt to minor shifts in the pipeline route. |

Tensile Strength | These fittings withstand tension, maintaining system integrity. |

Impact Resistance | They resist sudden forces, ensuring durability in dynamic environments. |

The flexibility of HDPE pipe fittings also supports installation in cold climates. The material maintains its toughness and does not become brittle at low temperatures. This advantage reduces the risk of leaks or breaks during seasonal changes. In addition, the chemical resistance of HDPE ensures safe transport of various fluids, further enhancing system reliability.

Note: Flexibility in pipe design reduces the need for additional joints or supports, which simplifies installation and lowers overall project costs.

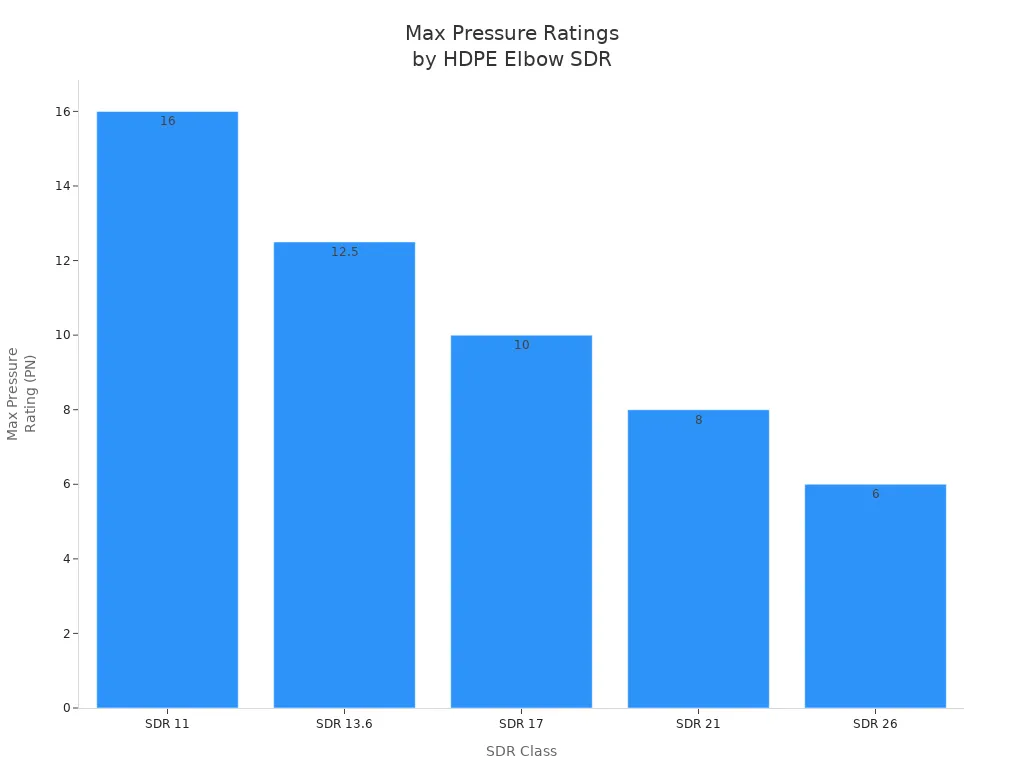

Pressure rating is a critical factor in selecting the right pipe fitting for any system. The pressure class, often referred to as PN (Pressure Nominal), indicates the maximum pressure the fitting can withstand at a standard temperature, usually 20°C. HDPE elbows are available in a range of SDR (Standard Dimension Ratio) classes, each with a corresponding pressure rating.

SDR Class | Typical Wall Thickness | Standard PN Rating (for PE100 at 20°C) |

|---|---|---|

SDR 11 | Thicker wall | PN16 |

SDR 13.6 | Medium wall | PN12.5 |

SDR 17 | Standard wall | PN10 |

SDR 21 | Thinner wall | PN8 |

SDR 26 | Thinner wall | PN6 |

XFusing’s product line covers all major SDR classes, ensuring that each pipe system can be designed for the required operating pressure. Proper selection of pressure rating extends the service life of the installation and minimizes the risk of failure.

Maintenance requirements for HDPE pipe fittings are minimal compared to traditional materials. The hydrophilic nature and chemical tolerance of HDPE reduce the likelihood of scaling, corrosion, or chemical attack. This characteristic means that fittings require less frequent inspection and intervention.

HDPE fittings do not corrode, which eliminates the need for painting or cathodic protection.

The durability of the material extends maintenance intervals, supporting long-term planning for municipalities and industrial operators.

Reduced maintenance needs translate to lower total cost of ownership over the lifespan of the pipe system.

Tip: Routine visual inspections and occasional cleaning are usually sufficient to maintain optimal performance in HDPE pipe networks.

HDPE’s reliability and low maintenance profile make it a preferred choice for critical infrastructure projects where downtime must be minimized.

Selecting the right HDPE elbow begins with a clear understanding of your application requirements. Each project has unique demands based on the type of fluid, pressure, and system configuration. For municipal water supply, reliability and compliance with safety standards are essential. Industrial systems may require resistance to aggressive chemicals or high temperatures. Agricultural irrigation often prioritizes flexibility and ease of installation. Consider the flow direction changes, the number of bends, and the required angle for each connection. Matching the elbow type to the specific pipe system ensures optimal performance and reduces the risk of future complications.

Tip: Consult with engineering professionals or suppliers like XFusing to verify that the selected fitting meets all technical and regulatory requirements for your application.

Project budgets play a significant role in the selection process. The initial cost of fittings, equipment, and labor can vary widely between different joining methods. For example, electrofusion elbows require specialized welding machines and trained personnel, leading to higher upfront costs. Butt fusion elbows, on the other hand, often involve lower equipment expenses and can be installed by workers with general skills. Ongoing maintenance and labor requirements also influence the total project cost.

Aspect | Electrofusion | Butt Fusion |

|---|---|---|

Initial Equipment Cost | Higher | Lower |

Ongoing Maintenance Cost | Moderate | Low |

Labor Requirements | Specialized training | General skills |

When planning your project, evaluate the efficiency of each method based on the timeline. Consider the availability of skilled labor and the desired speed of installation. Projects with tight deadlines may benefit from fittings that offer quick assembly, even if the initial investment is higher. XFusing provides a range of options to accommodate both cost-sensitive and high-performance projects.

Environmental conditions at the installation site can significantly impact the choice of HDPE fittings. Outdoor and underground installations require careful assessment of several factors:

Temperature: Select fittings rated for the expected operating temperature and pressure to ensure long-term reliability.

Chemical compatibility: Ensure the chosen material can withstand any chemicals present in or around the system to prevent leaks or degradation.

UV resistance: For installations exposed to sunlight, use fittings designed to resist UV breakdown and maintain durability.

Soil conditions: Evaluate the soil type, support, and installation depth to guarantee proper stability and performance.

Properly matching the fitting to the environment helps prevent premature failure and extends the service life of the system. XFusing’s product line includes solutions engineered for a wide range of environmental challenges, supporting both above-ground and buried applications.

Maintenance and longevity play a pivotal role in the selection of HDPE pipe elbows for any project. The long-term performance of a piping system depends not only on the initial quality of the fittings but also on how well they withstand operational and environmental stresses over time. HDPE elbows, when manufactured from premium PE100 material and installed correctly, can deliver exceptional durability.

The expected lifespan of HDPE pipes and fittings can exceed 100 years under optimal conditions. This makes them a preferred choice for infrastructure projects that demand minimal intervention over decades.

Material quality directly impacts longevity. High-grade PE100 elbows, such as those from XFusing, offer superior resistance to cracking, abrasion, and chemical attack.

Installation practices matter. Proper bedding and backfill materials help prevent external damage and stress concentration, which can extend the service life of the elbows.

Environmental factors, including soil composition, temperature fluctuations, and exposure to chemicals, influence the durability of HDPE elbows. Selecting elbows rated for the specific environment ensures consistent performance.

Routine maintenance for HDPE elbows is generally straightforward. Most systems require only periodic visual inspections to check for leaks, deformation, or joint integrity. The non-corrosive nature of HDPE eliminates the need for painting or cathodic protection, reducing ongoing maintenance costs.

Tip: For long-term projects, prioritize HDPE elbows with proven track records of durability and minimal maintenance requirements. This approach reduces total lifecycle costs and supports uninterrupted system operation.

When planning for longevity, consider the following:

Choose elbows that comply with international standards, such as ISO4427 and ASTM D3261, to ensure consistent quality.

Evaluate the compatibility of the elbow type with the intended joining method. For example, electrofusion and butt fusion elbows often provide the most robust, leak-proof joints for critical applications.

Assess the ease of future maintenance. Compression and threaded elbows allow for quick disassembly and replacement, which can be advantageous in systems that require regular modifications.

Selecting the right HDPE elbow type based on maintenance and longevity considerations helps safeguard your investment and ensures reliable performance for years to come.

Selecting the right HDPE elbow type requires careful evaluation of both technical and operational factors. Recent studies highlight that choosing the correct HDPE grade and wall thickness can extend service life and reduce maintenance. Unexpected issues, such as downtime and safety risks, often result from poor fitting selection.

Experts recommend:

Analyzing project requirements

Assessing application and operating conditions

Considering system design and connection types

Consulting with experienced suppliers like XFusing ensures optimal performance and long-term reliability for your piping systems.

Injection-molded elbows use a molding process for consistent dimensions and mass production. Fabricated elbows are custom-made by cutting and welding pipe segments, allowing for unique angles and larger sizes.

Check the system’s operating pressure and temperature. Match these requirements with the SDR class and PN rating of the elbow. Consult technical data sheets or XFusing’s support team for guidance.

Yes. HDPE elbows resist corrosion, chemicals, and UV exposure. They perform well in both above-ground and buried applications, provided you select the right grade and follow proper installation practices.

Yes. Electrofusion elbows allow for precise, leak-proof joints in repair scenarios. They require minimal excavation and can be installed in confined spaces.

You only need basic hand tools, such as a pipe cutter and wrench. No welding equipment or electricity is required, making installation quick and straightforward.

HDPE elbows can last over 50 years under normal operating conditions. Their durability depends on material quality, installation, and environmental factors.

Standard | XFusing Compliance |

|---|---|

ISO4427 | ✔ |

ASTM D3261 | ✔ |

NSF | ✔ |

XFusing’s HDPE elbows meet major international standards for safety and performance.

Yes. Threaded HDPE elbows can be disassembled and reused in different systems. This feature supports flexible system modifications and maintenance.